Manufacturers need to manage more than just machines – from inventory to supply chain, demand forecasting, and workforce safety. At Prajna AI, we understand the complexities involved in delivering a quality product. That’s why our solutions are designed to provide you the real-time insights every single time so you or your customer do not experience any bottlenecks. From predictive maintenance to demand forecasting, we have covered you at every stage. See how our solutions work with a free demo today!

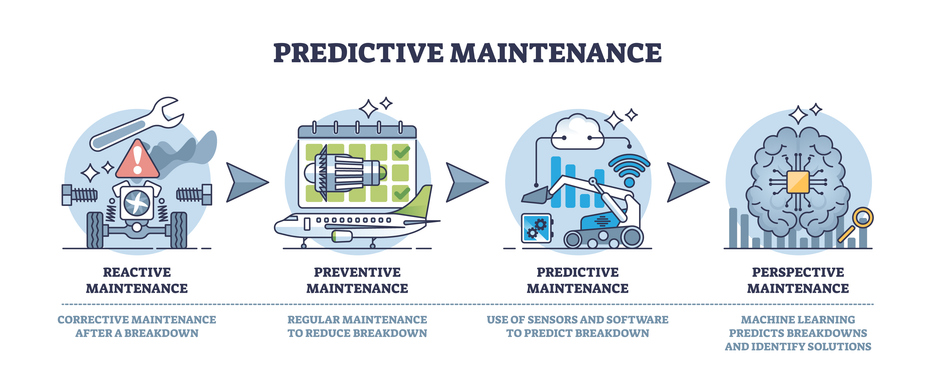

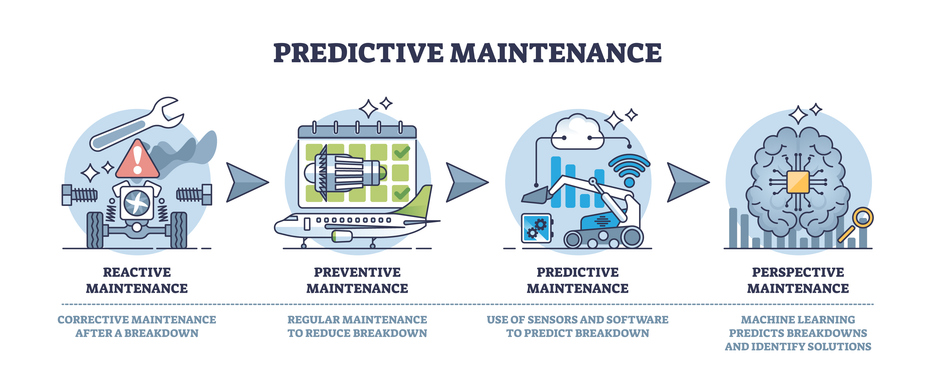

- Unexpected equipment failures leading to costly production halts

- Difficulty in scheduling maintenance proactively

- High maintenance costs due to reactive repairs

- Difficulty in predicting the remaining useful life of assets

Key Pain Points:

- DocuDigest

- GrasPh

- ImaGenetiX

Our Solutions

- Enhance equipment reliability and reduce unplanned production stops with AI-based predictive maintenance. Our intelligent analytics platform processes sensor data to forecast equipment failures, enabling proactive maintenance scheduling. Manufacturers experience improved asset lifespan, reduced repair costs, and maximized plant uptime.

Our Solution offers:

- Manual inspection processes are time- consuming, error-prone, and labor- intensive

- Difficulty in detecting subtle defects in products

- Maintaining consistent quality standards across production lines

- High costs associated with product recalls and rework

Key Pain Points:

- DocuDigest

- DocGenetiX

Our Solutions

- Improve product quality and inspection accuracy with AI-powered visual inspection systems. Our solution uses computer vision to detect defects in real time, ensure consistent standards, and eliminate manual errors. This leads to higher product integrity, reduced recall risks, and optimized manufacturing efficiency.

Our Solution offers:

- Keeping up with changing regulations

- Error-prone manual compliance processes

- Risk of fines and reputational damage

- Challenges monitoring transactions for suspicious activity

- Difficulties preventing financial crime

Key Pain Points:

- DocuDigest

- DocGenetiX

- GrasPh

Our Solutions

- Streamline end-to-end supply chain operations using AI. Our solutions enable real-time monitoring, compliance automation, and predictive logistics management. Manufacturers gain agility in responding to disruptions, maintain regulatory standards, and optimize inventory and distribution for operational excellence.

Our Solution offers:

- Inaccurate demand forecasts leading to stockouts or excess inventory

- Difficulty in predicting seasonal and cyclical demand patterns

- Inefficient inventory management practices resulting in high holding costs and obsolescence

- Poor customer service due to stockouts and delayed order fulfillment

Key Pain Points:

- DocuDigest

- DocGenetiX

- GrasPh

Our Solutions

- Forecast demand accurately and optimize inventory levels with AI-powered predictive analytics. Our platform analyzes historical trends, seasonal patterns, and external data to fine-tune stock planning. Manufacturers benefit from reduced stockouts, lower holding costs, and improved order fulfillment rates.

Our Solution offers:

- Unexpected equipment failures leading to costly production halts

- Difficulty in scheduling maintenance proactively

- High maintenance costs due to reactive repairs

- Difficulty in predicting the remaining useful life of assets

Key Pain Points:

- DocuDigest

- GrasPh

- ImaGenetiX

Our Solutions

- Enhance equipment reliability and reduce unplanned production stops with AI-based predictive maintenance. Our intelligent analytics platform processes sensor data to forecast equipment failures, enabling proactive maintenance scheduling. Manufacturers experience improved asset lifespan, reduced repair costs, and maximized plant uptime.

Our Solution offers:

- Manual inspection processes are time- consuming, error-prone, and labor- intensive

- Difficulty in detecting subtle defects in products

- Maintaining consistent quality standards across production lines

- High costs associated with product recalls and rework

Key Pain Points:

- DocuDigest

- DocGenetiX

Our Solutions

- Improve product quality and inspection accuracy with AI-powered visual inspection systems. Our solution uses computer vision to detect defects in real time, ensure consistent standards, and eliminate manual errors. This leads to higher product integrity, reduced recall risks, and optimized manufacturing efficiency.

Our Solution offers:

- Keeping up with changing regulations

- Error-prone manual compliance processes

- Risk of fines and reputational damage

- Challenges monitoring transactions for suspicious activity

- Difficulties preventing financial crime

Key Pain Points:

- DocuDigest

- DocGenetiX

- GrasPh

Our Solutions

- Streamline end-to-end supply chain operations using AI. Our solutions enable real-time monitoring, compliance automation, and predictive logistics management. Manufacturers gain agility in responding to disruptions, maintain regulatory standards, and optimize inventory and distribution for operational excellence.

Our Solution offers:

- Inaccurate demand forecasts leading to stockouts or excess inventory

- Difficulty in predicting seasonal and cyclical demand patterns

- Inefficient inventory management practices resulting in high holding costs and obsolescence

- Poor customer service due to stockouts and delayed order fulfillment

Key Pain Points:

- DocuDigest

- DocGenetiX

- GrasPh

Our Solutions

- Forecast demand accurately and optimize inventory levels with AI-powered predictive analytics. Our platform analyzes historical trends, seasonal patterns, and external data to fine-tune stock planning. Manufacturers benefit from reduced stockouts, lower holding costs, and improved order fulfillment rates.

Our Solution offers: