A Complete Toolkit for Smarter, Safer, and More Profitable Operations

Unplanned downtime is not merely an operational inconvenience; it is a significant financial drain on the manufacturing industry, costing as much as $50 billion annually. The average unplanned downtime event can inflict a financial impact of up to $2 million. This staggering cost, combined with persistent challenges such as elongated lead times and rising transport costs, creates a compelling need for a fundamental shift in maintenance strategy.

This report examines how artificial intelligence (AI) and a spectrum of machine learning models can transform maintenance from a reactive, costly necessity into a strategic driver of profitability and operational resilience. The analysis will outline a comprehensive AI toolkit, provide quantifiable return on investment (ROI) metrics supported by real-world case studies, and present a clear, four-pillar roadmap for successful implementation. Let’s go through the detailed path for executives to move beyond the limitations of traditional maintenance and harness the power of intelligent systems to secure a competitive advantage.

The Unseen Costs of Maintenance: From Reactive to Resilient

The Tangible and Intangible Costs of Downtime

The financial impact of equipment failure extends far beyond the immediate cessation of production. The tangible costs include lost revenue, which can be calculated by multiplying lost production units by revenue per unit. Furthermore, reactive maintenance is significantly more expensive, with emergency repairs and equipment replacement costs often running two to five times higher than those associated with a proactive program. A fragmented maintenance approach also hampers strategic decisions, as operational data is often isolated from crucial business systems like ERP or CMMS, making it impossible to calculate the true total cost of ownership (TCO) or budget effectively for spare parts.

Beyond the balance sheet, the intangible costs of downtime erode long-term value. These include brand damage, supply chain disruptions, customer dissatisfaction from late deliveries, and potential legal or regulatory penalties. The Deloitte 2025 Manufacturing Industry Outlook report highlights that while production material lead times have improved post-pandemic, they remain longer than before 2020, and over 35% of manufacturers cite rising transport costs as a key challenge. Unplanned downtime exacerbates these vulnerabilities by disrupting schedules and straining already-pressured supply chains.

The most critical and often overlooked costs are the higher-order risks to human safety and environmental impact. A predictive AI model implemented at a major Canadian utility, for instance, was able to prevent a potential wastewater spill by detecting a sensor malfunction, demonstrating that the value of AI-driven maintenance can extend to protecting the public and the environment.

The Limitations of Traditional Approaches

The reliance on outdated maintenance strategies is a core contributor to these challenges. Reactive maintenance, a “fix-it-when-it-breaks” approach, is inherently unpredictable and leads to a cycle of escalating costs and operational instability. It shortens equipment lifespans, increases safety risks, and makes it impossible to plan work schedules efficiently.

Preventive maintenance represents an improvement, as it involves scheduled repairs based on time intervals or usage patterns. However, it remains fundamentally inefficient. This calendar-based approach can lead to over-maintenance of healthy equipment, wasting labor and resources, or, conversely, a catastrophic failure in an asset that degrades faster than expected. The U.S. Department of Energy reports that predictive maintenance can yield a return on investment of roughly ten times the cost, largely because it eliminates this waste. A primary challenge underpinning these traditional models is fragmented and inconsistent data, which prevents the creation of a single “source of truth” and blocks rapid decision-making.

Source: U.S. Department of Energy

The AI Toolkit: A Spectrum of Intelligence for the Modern Factory

AI provides a sophisticated toolkit for overcoming the limitations of traditional maintenance. These tools range from foundational models that predict failure to advanced systems that can optimize complex decisions in real time.

Traditional Machine Learning: The Foundation of Prediction

- Supervised Learning: The Precision Predictor

Supervised learning models are trained on a labeled dataset of historical information, where input features are mapped to a specific output. In predictive maintenance, these models are used for two primary functions:

- Classification: This involves predicting a discrete outcome, such as whether an asset is in a “Healthy” or “Failing” state based on sensor data patterns. A logistic regression model, for example, can assign a probability to a binary outcome, allowing a team to act on a prediction before a failure occurs.

- Regression: This approach predicts a continuous value, such as an asset’s Remaining Useful Life (RUL) in hours or days. Regression models offer more detailed and nuanced information to maintenance teams than a simple “yes/no” classification, allowing for more precise scheduling and resource allocation.

- Unsupervised Learning: The Anomaly Hunter

In manufacturing environments, a lack of labeled failure data is a common and significant barrier to deploying supervised models. Unsupervised learning bypasses this limitation by training on data from only normal, “healthy” operations. These models build a “health signature”—a mathematical description of an asset’s normal temperature, vibration, and energy consumption. Any deviation or anomaly from this baseline behavior triggers an alert, allowing maintenance teams to detect potential issues long before they become visible to an operator or cause a breakdown.

Advanced Models for Dynamic Optimization and Simulation

- Reinforcement Learning (RL): The Dynamic Optimizer

Reinforcement learning represents a powerful evolution from simple prediction to strategic decision-making. In this paradigm, a software agent learns to operate within a dynamic environment to maximize a long-term reward. By continuously interacting with the production environment, the agent learns to optimize maintenance schedules by balancing the costs of performing maintenance against the risks of equipment failure and lost production. This capacity for adaptive, real-time decision-making in a complex environment addresses a fundamental challenge that traditional, static planning cannot solve. Training these models often begins in a simulated environment before being deployed in the real world, a process that mitigates the risk and cost of trial-and-error in a live production facility.

- Generative AI (GenAI) and Digital Twins: The Future of What-If Scenarios

A digital twin is a virtual replica of a physical asset, system, or process that consolidates fragmented data into a unified, real-time view. This technology directly addresses the data fragmentation problem that plagues many manufacturers. The integration of generative AI adds a new dimension of capability by giving the digital twin the ability to “imagine and craft entirely new futures”. With GenAI, manufacturers can simulate complex “what-if” scenarios to test maintenance strategies, predict outcomes, and identify early-stage risks in a virtual environment before they manifest in the real world. This powerful combination allows for accelerated design cycles and enhanced facility management, leading to improved operational resilience and deeper strategic foresight.

Proven Success: Quantifying the ROI of AI-Powered Maintenance

Real-World Case Studies

The practical benefits of AI-powered maintenance are demonstrated by a number of successful implementations:

- General Motors (GM): To address downtime at its Arlington Assembly Plant, GM, one of the largest automakers in the U.S, deployed IIoT sensors on legacy machinery, including conveyor motors and robotic arms. The AI system predicted over 70% of equipment failures at least 24 hours in advance, enabling maintenance teams to shift their focus from reactive fixes to proactive, high-value tasks.

- Siemens & Sachsenmilch: In a pilot project at a modern 24/7 milk processing plant, Siemens’ AI-powered solution, Senseye Predictive Maintenance, successfully detected a faulty pump early. This single intervention resulted in significant cost savings in the “low six figures,” providing a powerful illustration of the value of proactive intervention.

- Canadian Utility: A major Canadian utility partnered with a consulting firm to develop an AI algorithm to monitor thousands of aging sensors. This model detected anomalies and potential failures in real time, preventing a possible wastewater spill and showcasing the value of AI in mitigating critical risks beyond financial costs.

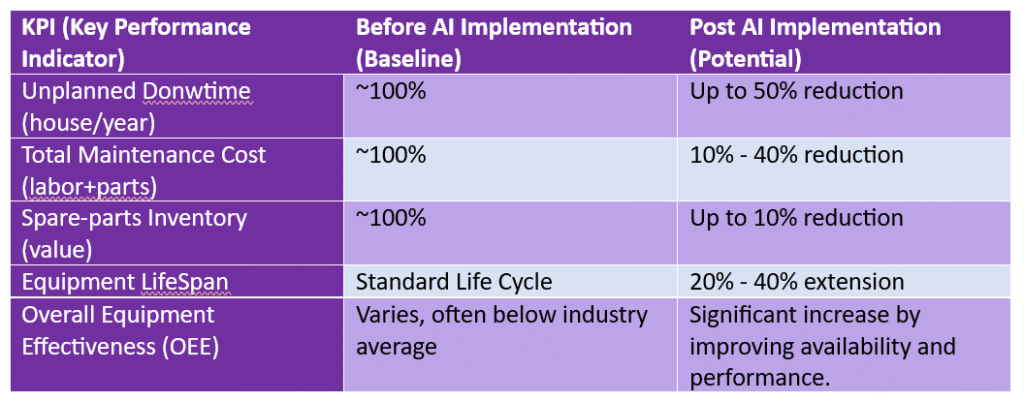

Core Maintenance KPIs: Pre- and Post-AI Implementation

Source:

- https://connectpoint.eu/8-challenges-solved-by-predictive-maintenance/

- https://www.oxmaint.com/blog/post/return-on-investment-for-predictive-maintenance

A Strategic Roadmap: From Pilot to Enterprise-Wide Adoption

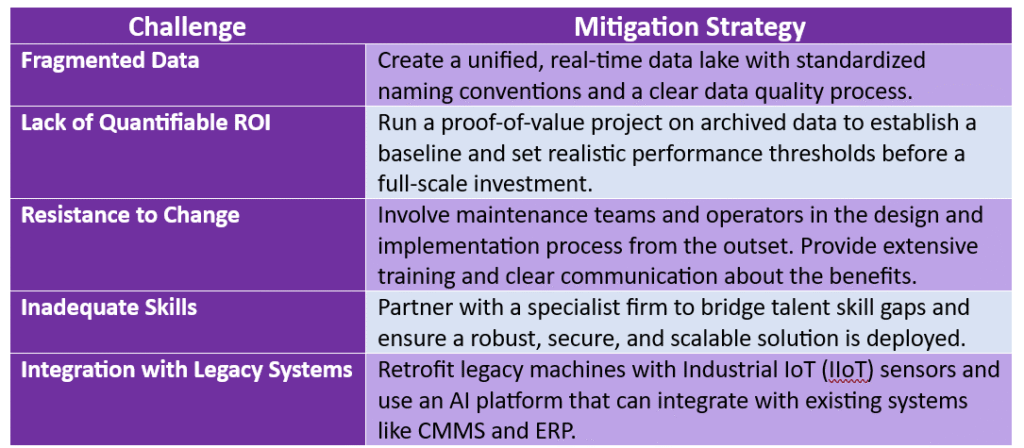

Successful AI adoption in manufacturing is not primarily a technology challenge but a strategic and organizational one. Companies must navigate several common pitfalls to transition from promising pilot projects to enterprise-wide adoption. A recent MIT study, for example, revealed that several of business attempts to integrate AI are failing. While the methodology of this particular study has been criticized for its narrow definition of success, it serves as a powerful reminder for executives to be strategic in their approach and not fall victim to “shiny object syndrome”.

The Four Pillars of Successful Implementation

- Define a Clear Business Problem: The first step is to avoid adopting AI simply to “keep up.” Instead, identify a specific, high-value business problem to solve, such as a particular machine that causes frequent downtime or a recurring issue with product quality. A focused objective strengthens the business case and increases the likelihood of a successful outcome.

- Prioritize Data Readiness: AI models are only as good as the data they learn from. Many AI projects fail because of fragmented, dirty, or inconsistent data. A successful strategy involves creating a shared, real-time data lake, normalizing tag names, and implementing a formal process for data quality validation.

- Start Small and Scale Strategically: An “all-or-nothing” approach to AI implementation is often a recipe for failure. The most effective strategy is to begin with a small-scale pilot project on a critical asset. Proving value in a controlled environment builds confidence, mitigates financial risk, and provides a blueprint for wider deployment.

- Cultivate a People-Centric Approach: AI is a support tool, not a replacement for skilled workers. Successful implementation hinges on involving front-line workers from the beginning, providing hands-on training, and clearly communicating how AI will empower them to work more efficiently and safely. This approach helps overcome skepticism and ensures that the technology is adopted and trusted by the people who use it every day.

Common AI Implementation Challenges & Mitigations for Manufacturing

Source:

- https://connectpoint.eu/8-challenges-solved-by-predictive-maintenance/

- https://imubit.com/article/ai-adoption-in-manufacturing/

- https://www.mckinsey.com/capabilities/mckinsey-digital/our-insights/superagency-in-the-workplace-empowering-people-to-unlock-ais-full-potential-at-work

The Bottom Line: Compelling ROI Metrics

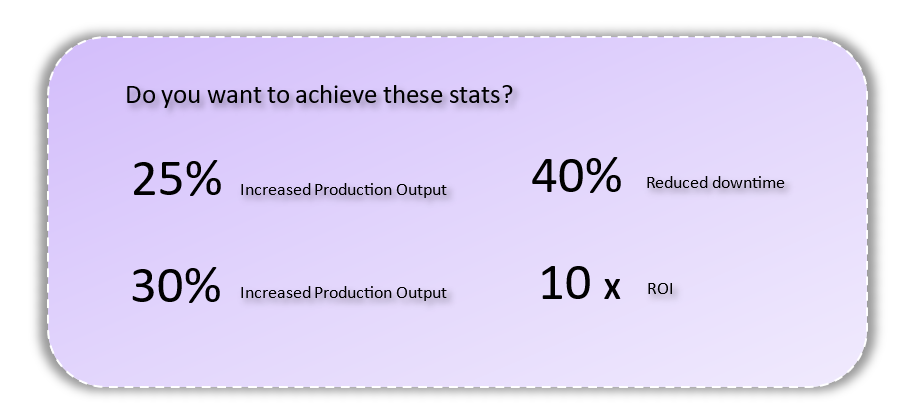

AI-powered predictive maintenance offers a clear and compelling business case. The U.S. Department of Energy reports that this approach can yield an ROI of approximately 10 times the initial investment. This value is realized through direct improvements in critical operational metrics.

A successful predictive maintenance program can lead to:

- Reduced Unplanned Downtime: Various studies have showna potential reduction of up to 50% in unplanned downtime, which is the single most significant driver of value.

- Lower Maintenance Costs: A decrease of 10% to 40% in overall maintenance expenses by performing targeted, condition-based repairs and eliminating unnecessary work.

- Extended Asset Lifespan: An increase in equipment life by 20% to 40% by preventing premature wear and tear.

- Improved Overall Equipment Effectiveness (OEE): Predictive maintenance directly enhances OEE by increasing equipment availability (reducing unplanned downtime) and optimizing performance (ensuring machines run at peak efficiency).

- Smarter Inventory Management: A reduction in MRO (Maintenance, Repair, and Operations) inventory spend by as much as 10% by accurately forecasting which spare parts are needed and when.

From Data Chaos to Predictive Clarity

This is where Prajna AI delivers value. Our Gen AI solutions—DocuDigest, GrasPh, and ImaGenetiX—are purpose-built to unify fragmented data, extract actionable intelligence, and deliver predictive insights that technical teams can trust. DocuDigest enables rapid data summarization and query, GrasPh creates a dynamic knowledge graph that connects operational and enterprise data, and ImaGenetiX converts complex, image-based records into structured intelligence. Together, they empower engineering and operations teams with real-time anomaly detection, condition-based monitoring, and the foundation for other AI powered solutions. With Prajna AI, maintenance shifts from firefighting failures to proactively shaping resilient, high-performing operations.